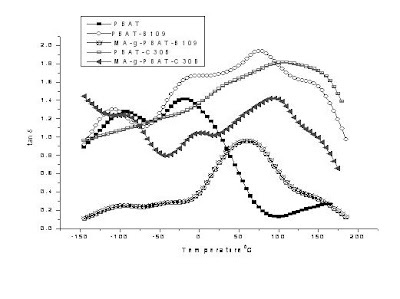

The primary dispersion peak is due to the motion of the polybutylene adipate unit whereas the secondary peaks corresponding to terephthalate unit. Hence, Tg of the virgin corresponds to the low temperature transition of Tanδ at -20°C. It is evident that incorporation of the nanoclays result in increase in the glass transition temperature of the matrix from -20°C to -13°C. Further, the grafted sample showed an additional shift in Tg to a comparatively higher temperature -12.03°C and -11.39°C MA-g-PBAT/C30B and MA-g-PBAT/B109 respectively. This indicates an enhancement of interfacial adhesion between the filler and the biopolymer due to the segmental immobilization of polymer chains in the presence of fillers as well as improved dispersion characteristics due to exfoliation of the clay galleries. The secondary transition peak corresponding to the terephthalate unit of the biopolymer also shifted to higher temperature regions in both ungrafted and grafted nanocomposite hybrids.

The primary dispersion peak is due to the motion of the polybutylene adipate unit whereas the secondary peaks corresponding to terephthalate unit. Hence, Tg of the virgin corresponds to the low temperature transition of Tanδ at -20°C. It is evident that incorporation of the nanoclays result in increase in the glass transition temperature of the matrix from -20°C to -13°C. Further, the grafted sample showed an additional shift in Tg to a comparatively higher temperature -12.03°C and -11.39°C MA-g-PBAT/C30B and MA-g-PBAT/B109 respectively. This indicates an enhancement of interfacial adhesion between the filler and the biopolymer due to the segmental immobilization of polymer chains in the presence of fillers as well as improved dispersion characteristics due to exfoliation of the clay galleries. The secondary transition peak corresponding to the terephthalate unit of the biopolymer also shifted to higher temperature regions in both ungrafted and grafted nanocomposite hybrids.Wednesday, August 27, 2008

Damping factor - Project1

5.2. Damping factor (Tanδ)

The primary dispersion peak is due to the motion of the polybutylene adipate unit whereas the secondary peaks corresponding to terephthalate unit. Hence, Tg of the virgin corresponds to the low temperature transition of Tanδ at -20°C. It is evident that incorporation of the nanoclays result in increase in the glass transition temperature of the matrix from -20°C to -13°C. Further, the grafted sample showed an additional shift in Tg to a comparatively higher temperature -12.03°C and -11.39°C MA-g-PBAT/C30B and MA-g-PBAT/B109 respectively. This indicates an enhancement of interfacial adhesion between the filler and the biopolymer due to the segmental immobilization of polymer chains in the presence of fillers as well as improved dispersion characteristics due to exfoliation of the clay galleries. The secondary transition peak corresponding to the terephthalate unit of the biopolymer also shifted to higher temperature regions in both ungrafted and grafted nanocomposite hybrids.

The primary dispersion peak is due to the motion of the polybutylene adipate unit whereas the secondary peaks corresponding to terephthalate unit. Hence, Tg of the virgin corresponds to the low temperature transition of Tanδ at -20°C. It is evident that incorporation of the nanoclays result in increase in the glass transition temperature of the matrix from -20°C to -13°C. Further, the grafted sample showed an additional shift in Tg to a comparatively higher temperature -12.03°C and -11.39°C MA-g-PBAT/C30B and MA-g-PBAT/B109 respectively. This indicates an enhancement of interfacial adhesion between the filler and the biopolymer due to the segmental immobilization of polymer chains in the presence of fillers as well as improved dispersion characteristics due to exfoliation of the clay galleries. The secondary transition peak corresponding to the terephthalate unit of the biopolymer also shifted to higher temperature regions in both ungrafted and grafted nanocomposite hybrids.

The primary dispersion peak is due to the motion of the polybutylene adipate unit whereas the secondary peaks corresponding to terephthalate unit. Hence, Tg of the virgin corresponds to the low temperature transition of Tanδ at -20°C. It is evident that incorporation of the nanoclays result in increase in the glass transition temperature of the matrix from -20°C to -13°C. Further, the grafted sample showed an additional shift in Tg to a comparatively higher temperature -12.03°C and -11.39°C MA-g-PBAT/C30B and MA-g-PBAT/B109 respectively. This indicates an enhancement of interfacial adhesion between the filler and the biopolymer due to the segmental immobilization of polymer chains in the presence of fillers as well as improved dispersion characteristics due to exfoliation of the clay galleries. The secondary transition peak corresponding to the terephthalate unit of the biopolymer also shifted to higher temperature regions in both ungrafted and grafted nanocomposite hybrids.

The primary dispersion peak is due to the motion of the polybutylene adipate unit whereas the secondary peaks corresponding to terephthalate unit. Hence, Tg of the virgin corresponds to the low temperature transition of Tanδ at -20°C. It is evident that incorporation of the nanoclays result in increase in the glass transition temperature of the matrix from -20°C to -13°C. Further, the grafted sample showed an additional shift in Tg to a comparatively higher temperature -12.03°C and -11.39°C MA-g-PBAT/C30B and MA-g-PBAT/B109 respectively. This indicates an enhancement of interfacial adhesion between the filler and the biopolymer due to the segmental immobilization of polymer chains in the presence of fillers as well as improved dispersion characteristics due to exfoliation of the clay galleries. The secondary transition peak corresponding to the terephthalate unit of the biopolymer also shifted to higher temperature regions in both ungrafted and grafted nanocomposite hybrids.

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment